About Morgan Ranch Beef

The Nebraska Sandhills, in the direct center of the U.S., is a terrible place to live if you want to experience hot tub karaoke with runway models. However, if you care to produce fabulous beef, then it is one of the best locations in the world. Long before I was "The Meat Guy", I was just the youngest Morgan brother helping to keep the family ranch afloat. This mostly entailed performing all the tasks that no one else really wanted to do which is why I eventually ran away from home and didn't stop running until the credit cards maxed out in Japan. We Morgans have been cowboys for more generations as we can count, higher mathematics tending to be a hindrance to ranching anyway. The current ranch was founded by my Aunt Ollie back in 1934, which is once again, further back than we can count. There is a family rumor of her having run off as a teenager with a much older, and wealthier Texas oilman and this ranch was a part of his holdings. It's still a bit too early to tell that story however as the scandal is a might fresh. My parents later took over the operation, and my mother still reigns supreme as Matriarch with veto powers, which is why she is sometimes left out of the loop.

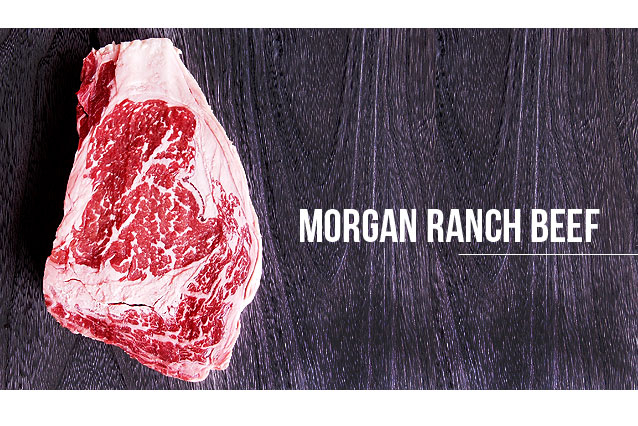

Cattlemen don't use the term "terroir" because it's one of those words that could easily get you into trouble if misunderstood. However, the story of the Morgan Ranch Beef begins with the story of the environment. Twenty miles Northwest of Burwell, Nebraska, a town known only for its rodeo, lies the 10,000-acre spread. Gentle rolling hills, native grassland as far as you can see, and an occasional cottonwood tree to mark what was once a homestead dugout, are the only features. This is the Nebraska Sandhills, a windswept region of sand dunes stabilized by grass that covers one-fourth of the State.

The Sandhills have never been a very popular place to live. There are no trees for logging so the first settlers had to dig holes in the ground, and there are no minerals in the earth for mining and its manufacturing offspring. All attempts to grow crops of any sort have been met with total failure because once the grass is plowed, the incessant wind just blows the seeds and topsoil away. Also, the winters are long, harsh, and cold and by mid-November, everybody is pretty damned sick of being asked "is it cold enough for ya?" Malcontents and cattle do exceptionally well in the Sandhills. Without all those pesky people that economic development brings, the natural environment is pristine and pollution free. Good water is essential to beef production and the Morgan Ranch has great water. All that sand acts as a filter and each pasture has a couple windmills that tap into the aquifer to pump natural mineral water for the cows. By the way, the reason why there are two windmills is because one will almost always be broken down requiring someone to crawl up the tower to make repairs (see above regarding running away from home). Great beef starts with great cattle and on the Morgan Ranch, the cattle are the rock stars. Seeking out genetically superior individuals, selectively breeding them, monitoring the outcome, and then repeating for generation after generation, that's the process and it takes decades to build a herd. While other ranches were breeding purely for traits like growth and size, we were trying to differentiate ourselves from the normal commodity markets. To that end, we focused on "eatability".

It may seem counter-intuitive, but it is actually very hard to selectively breed for yummy beef. If you are breeding something like chickens, it's much easier. You've got a bunch of chickens, you feed them for six weeks, you chuck them in the fryer, decide which one was tastiest, then start hatching eggs only from hens with the same bloodline. The only equipment needed is a sharp knife and some poor soul willing to pluck feathers. With beef cattle it takes a good three years from breeding to eating, there are phases in the growth cycle that have different nutritional requirements, and there are seasons with weather severity that can impact the final product. Finally, you need some pretty major equipment to slaughter and a really large family to eat your mistakes and tell you that you've been told so. My brothers figured out how to do it and it involved bringing some Japanese genetics into the herd and controlling the entire process from conception to consumption. It took years, but with no hostess bars in Nebraska, there really wasn't anything better to do.

Someday, somewhere, there will be a pub quiz offering a lifetime of free swill to the person who can name the four stomachs of a cow and it will be my chance to bask in glory. Shortly thereafter I will be carted away to rehab due to another one of those shitty surprise parties that my loved ones always call "interventions". Until that happens, the only other use for an in-depth knowledge of the amazing digestive qualities of everyone's favorite ruminant is to describe how important feeding is to beef production. This is trial and error process that takes us over 30 months to get feedback. To compare to chickens once again, a broiler takes six weeks. But that's another reason why chicken isn't really meat and is classified as a vegetable. It all starts on grass but there is far more to it than just turning out the cows and letting them graze. Calving happens in the spring for a good reason, that's when the grass starts growing. That green, first-growth grass makes the most nutrient dense milk which gives the calves the best start. If you time your calving too early, the grass isn't ready yet, if it's too late then it's gotten too hot, the grass isn't as good, the brood cows don't have as much appetite and the calf crop suffers. So each year during the month of April we attempt to calve out hundreds and hundreds of cows. This entails checking them every couple of hours for problems, doctoring for sickness, helping the babies nurse if they need it, and generally being knee deep in unpleasantness far more often than you would ever desire.

Having had three children myself I can say with certainty that it's not much different, except that with cattle, after weaning, you can get rid of the cows that caused you trouble at the sale barn and never have to see them again. Cattle are grazing machines that require constant maintenance with no spare parts. We are lucky on our ranch to be grazing on what is one of the most diverse grasslands anywhere. There is an incredibly large variety of natural fodder; this variety makes it possible for the cattle to have access to an abundance of vitamins and minerals during their high growth phase which establishes the basis for a successful finishing phase later on. Protecting that diversity of grass is the top priority and that means constantly checking on the cattle and moving them to fresh pastures to prevent overgrazing. As none of the ranches is irrigated, the timing is dependent on the weather and if you ever find yourself in Nebraska, you'll quickly notice that all conversations are somehow about the weather. I may be the only foreigner in Japan to be surprised at how little the Japanese talk about the weather. Marbling, tenderness, and taste are the three traits that separate the beef that makes a celebratory steak from what makes taco filling. It takes a mixture of nature and nurture and to get it just right and from this point forward, it's heavy on the nurture. We break up the finishing phase into two stages.

The first stage occurs in our dry lot pens out behind the area where we used to store haystacks and now store hay bales creatively called the "stack lot". The heifers that we've selected to be good enough for our Japan beef program are backgrounded here where they can slowly gain weight with a reasonably regular feeding schedule. It's a two-man operation with one person driving the feed truck and another watching the gate so that none of the calves get out. As we are a family operation, this never goes smoothly so nearly every feeding time is a mixture of cursing and blame, both of which are vital to maintaining the continuity of our corporate culture.

The next step requires a little professional intervention. When the animals are ready they are sent to the Cattle Club Med which is what our partner Mikey Burnham should have named his business. The part of Nebraska that is not the Sandhills is nearly all farming and within our area, we have local access to corn, distillers grains, alfalfa, silage and all kinds of feed bunk fodder. The Burnhams are professional cattle feeders who, unlike the Morgans, are able to accurately weigh proper rations and stick to a strict feeding schedule regardless of football or hangovers. This is where the cattle get fat and happy, fat and happy cattle are tasty cattle. Fat and happy middle-aged gaijin are just fat.

The final journey for our cattle takes place at one of the last family-owned slaughterhouses in the United States. J.F. O'Neill Packing is run by third generation Irish Americans with enough family to have a relative in every corner of the plant. It is here that the heifers are gently and humanely guided towards the light. My brother is there every time we process and I think it's mostly to observe a dysfunctional family from the outside for once. The plant is tiny with a maximum capacity of just a couple hundred head per day, compared to most corporate operations that kill thousands. Processing our beef at a small plant has some major advantages. This is a very critical stage and a mistake at this point can throw away three years of work. At our packing plant, we are able to do what is called a dry carcass chill. Normally, after the messy work of turning a steer into a side of beef is finished, the carcass hangs in a refrigerator and is showered with cold water. The reason for the water spray is to keep the hot carcass from losing any weight due to water evaporation. However, we avoid the water spray and hang it in the chiller for 2 - 3 times longer than normal. While this causes our costs to go up because of shrinkage, allowing the meat to dry out the extra 5% or so makes a beefy difference to the texture of the steak. It allows us to age and then freeze the meat without having a runny, limp disaster when the meat is thawed. Age makes steaks, wine, and wallets more full-bodied. In meat, aging allows enzymes to work at tenderizing the beef and increasing flavor. We age our beef for a minimum of 6 weeks before freezing.

If I knew then what I know now about importing meat, I'd be the "thong guy" or the "riding lawn mower guy" or maybe even the "English conversation guy" - anything but the "Meat Guy". In April of 2013 import restrictions on U.S. beef were relaxed. However a relaxation of the rules does not mean a relaxation of the process, we've had the honor of bringing in one of the first beef shipments to Nagoya and the very first shipment from our recently approved plant. That means that the authorities gave us lots of friendly attention, not the "hey, how are you? It's soooo nice to see you" kind of attention that I get down at Show Pub Starlight. It was the kind of attention that meant opening nearly every single carton, three times. I like Starlight better. Then it's a quick payment of the 38.5% customs duty and the meat is ours.

The last stop for Morgan Beef is portioning in our Nagoya plant. Here is where we slice and carve in our clean room to get it down to pan size. Place your order with us and we'll box it up and have it delivered to your door within a couple days. It was a long journey from the backcountry Nebraska Sandhills to your kitchen and for better or worse, there was a Morgan involved the whole way.